Achieving MES Web-Based Architecture for Life Sciences

Business Development Manager Roland Esquivel outlines one of our MES areas of expertise and how POMSnet software achieves web and cloud–based architecture

For over 30 years now it seems Pharma, Biotech, and Medical Device have paid a heavy price for Manufacturing Execution System MES license and implementation without realizing much more benefit than basic compliance for electronic batch records. There are not many other examples of million-dollar software implementation projects or capital investments based on “soft savings” or defect avoidance that I can think of – making people wonder why MES was every invested in the first place. Yet, MES historically has been justified in business cases and capital request this way. With investments at these levels, an ROI should deliver a clear competitive advantage for the supply chain not simply avoiding an FDA 483 Warning Letter. I know from personal experience evaluating multi MES companies the price tag quickly skyrocketed to nearly $20 million. Leadership had no appetite for investment at this level and pulled the plug on the project.

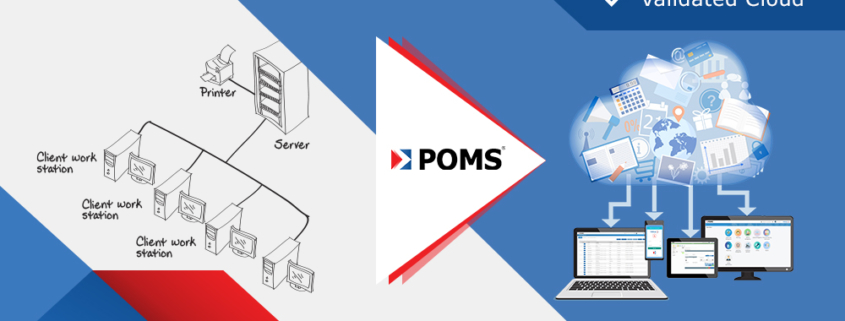

One reason for MES financial burden was the traditional server-client architecture of MES systems available on the market a few years ago. Configurable MES saves time in programming code yet falls short when it comes to cost and speed of implementation because of server-client architecture and validation required. With each client workstation on a manufacturing floor manually and locally configured to communicate with servers extra validation and troubleshooting during and after an MES implementation or hyper care is required. Companies often begrudgingly hire third-party service integrators to handle the validation and tend to over staff hyper care teams to avoid project risks this has become known as “throw money at the problem” mitigation. Certainly, one can see, client-server architecture is a formula for extensive maintenance cost, requires costly redundancy hardware, and an impedance to MES project implementation.

Today we see new industries in life science spawning overnight enabled by vastly new technologies being leveraged like robotics, data science, and genetic engineering. What were dreams just a few years ago are achievable today. Cell and Gene therapy commonly referred to as Personalized Medicine have matured from university trials to FDA approved treatments. Patients can now harvest their cell and gene codes to reintroduce as cures for cancers. Therapies for diabetes are utilizing wearable device monitoring and cloud-based technologies coupled with insulin delivery systems to create optimized treatments for patients. MES customers who once paid a heavy investment price are now seeing benefits, and the costs savings are being shared. New technologies like web-based have dramatically reduced MES costs, time to implement, and ROI basis are more tangible than ever.

Simply put traditional MES client-server architectures were too complicated, too much validation, and too costly to implement for today’s life sciences companies embarking on new patient therapies. When new product introductions are counted in months, there is no time for implementing client-server MES. In today’s marketplace readily available technologies and validated cloud infrastructures are being leveraged that make MES implementation easier, faster, and add value beyond simple compliance. POMS web-based (released 2004) and validated cloud-based (released 2014) architecture eliminate the burden and costs of client-server MES by removing on premise data base administrators, data centers, and precious real estate. As for performance, not to worry, high availability and distributed data canters will keep your web-based MES running like water. Today’s life science companies are leveraging this fact to count their own MES implementation in months and not years by taking advantage of POMSnet web-based and cloud-based MES.